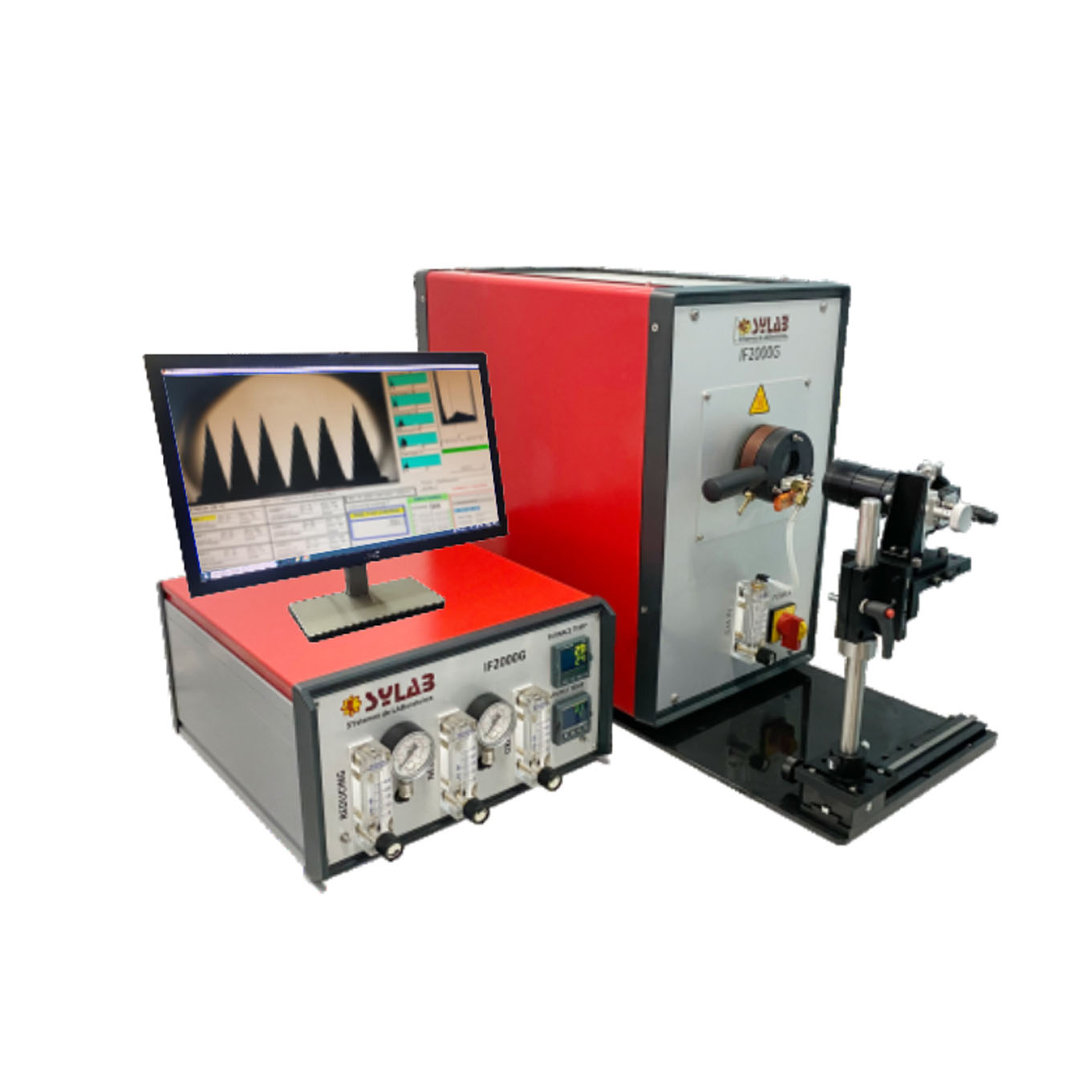

Sylab - Ash Fusion Analyzer - IF2000G-HDC & IF2000G-HDBM

Uses the Latest technology in the service of the fusion temperature determinations.

Sylab Ash Fusion Analyzer automatically determines four critical temperatures: Deformation Temperature (IT), Softening temperature (ST), Hemispherical Temperature (HT) and Fluid Temperatures (FT).

It is a Fully automatic instrument for determining the Ash Fusion points by means of Image analysis. Sylab’s Ash fusion analyzer uses modern technology for monitoring, computing, and storing results and curves obtained during the test. Up to 6 samples can be analysed in each batch.

Technical Specifications

| Ash Fusibility Determination | Automatic |

| Fusion Points | IT (Initial deformation Temperature), ST (Softening Temperature), HT (Hemisphere Temperature) & FT (Fluid/Flow Temperature) |

| Maximum Samples per Analysis | Up to 6 samples can be analyzed in each batch. |

| Test Method | ISO 540, ASTM D 1857, CEN/TS 15370-1, CEN/TR 15404, ASTM E 953-88 |

| Analysis Time | 3 runs per working day |

| Capable to Analyze | Cube, Cylinder, Truncated cone and Pyramids |

| Analysis atmosphere | Oxidizing Atmosphere/Reducing atmosphere |

| Sample shape identification | Automatic, Pyramid, Truncated cone, Pyramid and Cylinder |

| Temperature range | up to 1600 deg C |

| Temperature Ramp Rate | programmable 1 deg C to 12 deg C per minute |

| Heating elements | Silicon carbide (IF2000G-HDC), Lanthanum Chromite (IF2000G-HDBM) |

| Operating Condition | 15 deg C to 35 deg C |

| Relative Humidity | 20% to 80%, non-condensing |

| Safety | Integrated CO monitor with auditory alarm, gas flow stops on alarm |

Typical Sample Materials

Coal Ash

Coke Ash

RDF Ash