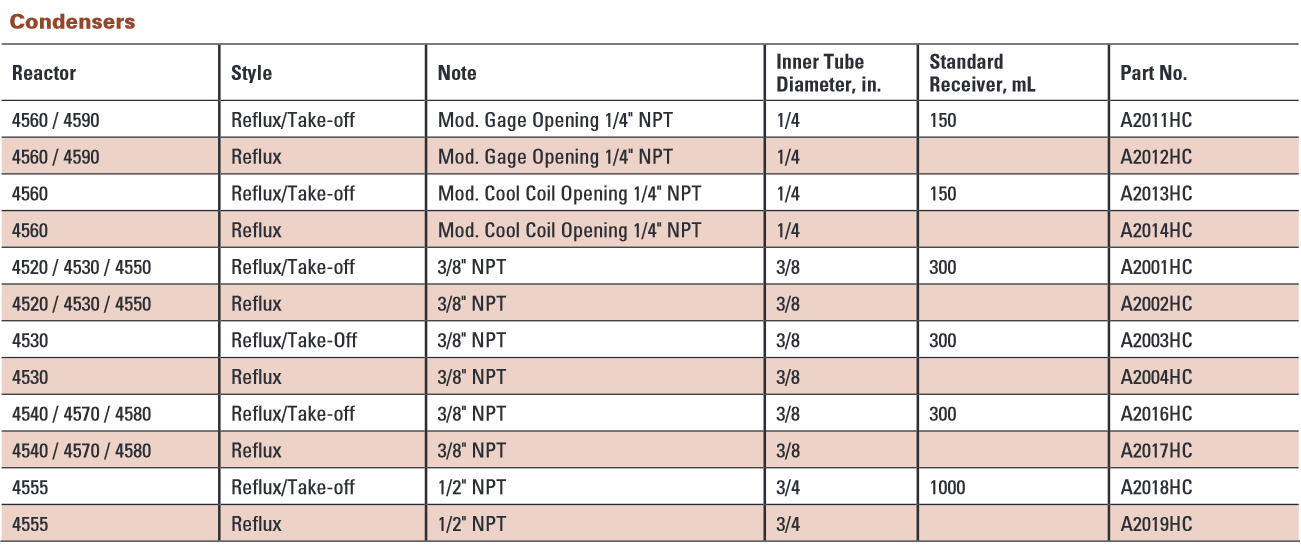

Parr offers two styles of condensers for attachment to the head of a stirred reactor or pressure vessel. These can be made in various sizes to match the size of the reactor

|

The reflux condenser consists of a length of tubing connected directly to the head of a vessel and equipped with a water cooling jacket. Condensed vapors are returned directly to the vessel and any non-condensable gases can be released through a needle valve at the top of the condenser. A helical insert in the condenser ensures maximum effectiveness in a rather short length. |

|

The reflux/take-off condenser consists of a water jacketed tube, the same as described above, assembled with a receiving vessel attached to the lower end of the condenser. Any vapor, such as water from a polymerization reaction, can be condensed and collected in the receiver, from which it can be with drawn through a bottom valve. Any non-condensable gases can be released through a needle |

Modifications

Many users opt to install a ball valve at the head of the reactor below the condenser to use as a shut-off to the condenser. Alternate collection vessel volumes are available upon request.The installation of a condenser on any of the Parr reactors requires a larger port in the head of the vessel, the size of which will vary with the volume of the reactor system. Due to the limited space on the 4560 mini reactors we would change either the gage opening or one of the cooling coil ports to 1/4″ NPT for use with a condenser. This modification would then either combine the gage and condenser functions or eliminate the internal cooling loop to accommodate the condenser. Reactors with volumes of 1 liter and greater would be modified with a 3/8″ NPT opening or larger depending on the reactor volume. The standard head fittings would be rearranged to accommodate this port

For assistance with condenser selection or customize condenser for your reactor, Click Here